Engines are used every day all over the world. All types of vehicles depend on them. For different uses, different types of engines are needed.

One type of internal combustion engine that is well known in the Wankel engine. It produces power from a rotor that spins.

You will find information in this article about how the Wankel engines work, types of Wankel engines, parts of the Wankel engine, and applications of Wankel engines.

What is Wankel Rotary Engine?

A rotary internal combustion engine is one with a curved, triangular or eccentrically pivoting piston that rotating around in as elliptical chamber creating three combustion spaces that are different in volume.

In simple words, it is an internal combustion engine that utilizes an eccentric rotary motion to convert pressure into rotary motion.

The German engineer, Felix Wankel invented a rotary engine known as the Wankel rotary engine. The Wankel rotary engine was mainly used in race cars. The Wankel engine is an Otto cycle engine but operates differently from reciprocating I.C. engines.

The Wankel engine is purely a rotary engine and does not have any reciprocating parts or pistons in any way. The Wankel engine produces more torque, lower vibration, and is for given power significantly smaller and lighter than reciprocating piston type engines.

It utilizes a rotor instead of a piston, which turns inside a chamber creating a further challenge and the next generation of engines beyond reciprocating type engines.

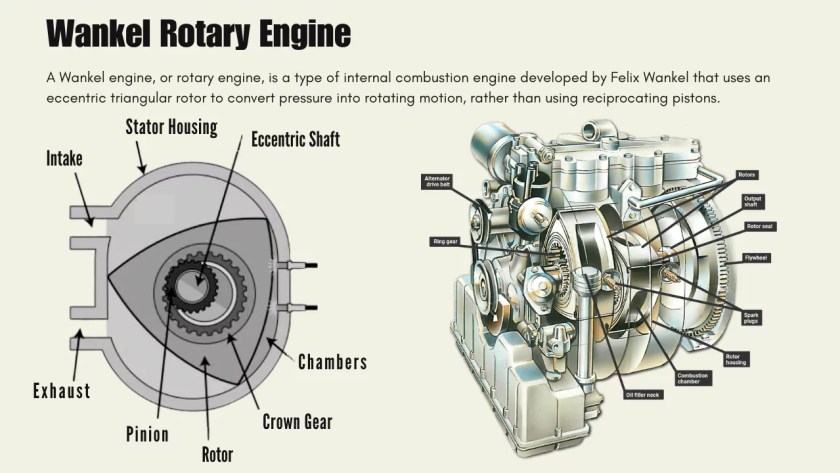

Parts of Wankel Rotary Engine

Below are the parts of a Wankel rotary engine:

- Intake

- Exhaust

- Crown gear

- Rotor

- Combustion chamber

- Housing

- Eccentric shaft

- Apex seal

- Spark plug

#1. Intake.

The intake begins when the tip of a rotor passes through the intake port. The rotor chamber is at its smallest position, resulting in the intake port moving inside the larger section as it spins.

#2. Exhaust.

As the rotor tip passes through the exhaust port, high-pressure exhaust gas can flow through the exhaust port.

#3. Crown Gear.

The crown gear in the Wankel engine has the teeth extending from the face of the crown gear at a right angle to the face of the wheel.

#4. Rotor.

The Wankel rotary engine uses a triangular-shaped rotor with three convex faces. Each face of the rotor acts as a piston. The rotor acts as the prime mover in the Wankel rotary engine.

The combustion is created by burning the fuel and has the combustion applied directly to the rotor surface, which causes the rotor to spin eccentrically.

On one side of the rotor, there is the internal timing gear that meshes with the fixed timing gear on the side housing to keep the correct relationship between the rotor and the eccentric shaft.

#5. Combustion Chamber.

The Wankel engine rotor rotates in an orbital motion located in a uniquely shaped housing which induces crescent-shaped combustion chambers between the rotor sides and the housing’s shaped wall.

#6. Housing.

The housing is oval-like and epitrochoid shaped which encloses a triangular rotor with bow-shaped faces on it resembling a Reuleaux triangle. The housing holds components like an inlet, outlet port, spark plug, water jacket, etc.

This engine has several housing cases, there are two important housing that are:

- Main Housing: Closed with side housing.

- Side Housing: Side housing consists of a fixed timing gear, which connects to the internal timing gear keeping the rotor in connection to the eccentric shaft in the correct way.

#7. Eccentric Shaft.

The “useful” part that converts the rotor’s eccentric motion into concentric motion and takes it out of the engine.

The rotors ride on an eccentric (similar to crankpin) integrated into the eccentric shaft (similar to a crankshaft). The rotor moves around the eccentric and uses orbital motion around the eccentric shaft.

#8. Apex Seal.

The triangular rotor’s sides create pistons, so this chamber must be sealed which is done using apex seals. The apex seals are curved metal in contact with the engine housing while the rotor moves.

#9. Spark Plug.

The Wankel engine uses two spark plugs, or a leading and trailing spark plug. The leading plug which resides at the bottom of the rotor housing burns approximately 95% of the air/fuel mixture creating a lot of power.

Construction of a Wankel Engine

The diagrams show a simplified version of a Wankel Rotary Engine.

The Wankel rotary engine uses a unique triangular rotor that moves around a central shaft. Each of the rotor’s three sides acts as a separate combustion chamber, which produces a four-phase cycle similar to a piston engine.

The Wankel engine operates on the intake, compression, power and exhaust cycle – the big difference from the reciprocating piston engine is that these cycles occur in separate spaces, not all in the same chamber.

A rotary engine creates pressure, transferred from the combustion of the fuel-air mixture, that is converted to rotary motion to power the vehicle.

Combustion Cycles of a Wankel Rotary Engine

The Wankel rotary engine operates in a four-phase combustion cycle.

#1. Intake.

During intake, the leading rotor apex passes the intake port on the rotor housing, and the rotor turns with the intake port open to induce air-fuel into the chamber.

After the rotor apex passes the intake port, it will close off that area for compression.

#2. Compression.

After the intake phase is done, the rotor continues through the rotor housing, continuing its eccentric motion and eliminating volume in the chamber as it compresses the air-fuel.

The chamber has achieved its minimum volume when the rotor reaches the spark plugs.

#3. Combustion.

Shortly before getting to a minimum volume, the spark plugs in the engine will ignite the compressed air-fuel mixture.

The pressure created by the expanding gases from the explosion pushes on the rotor flank. This pressure on the rotor’s flank creates torque and engine power as the rotary engine and rotor rotate.

#4. Exhaust.

The exhaust phase is the last of the cycle. During the exhaust phase, the rotor continues to turn after the ignition and squeezes out the combustion gas from the previous phase.

The gas leaves the chamber through the exhaust port. Once the exhaust phase is complete, the new intake phase begins and the cycle continues.

How the Wankel Engine work?

The Wankel rotor engine generally uses a three lobed rotor to create three areas of volume (spaces) in a oval shaped chamber. The four cycles of intake, compression, power, and exhaust occur simultaneously with the three spaces around the rotor while the engine is running.

Figures (i) show the intake of fuel in which the rotor side AB is creating suction, and the air/fuel mixture is entering the suction chamber from the carburetor. Then, as the rotor spins in a clockwise direction the air/fuel is being compressed between the rotor and chamber (ii).

Then, it reaches the ignition point and the burnt gases expand creating space (iii), which forces the ignition gases out the exhaust (iv). Rotor side AB is back in the starting position accepting a new charge from the suction chamber and the cycle is complete.

The same cycles of operation are happening at the same time with the three spaces of the rotor. The net result is three power impulses for one full rotation of the rotor which is at least three times better than a two-stroke engine and six times better than a four-stroke.

In essence, the engine provides nearly continuous power. The eccentric movement of the rotor creates and produces vibration, which can be moderated with a flywheel that is equally mounted to the rotor and engine casing.

Why is the Wankel Engine so rare?

Wankel engines are rare for a few reasons now:

#1. Low Thermal Efficiency.

The engine’s combustion chamber is long and irregularly shaped, so overall thermal efficiency is lower than in reciprocating engines because unburned fuel often blows out the tailpipe.

#2. Burn Oil.

Due to the engine designs, these engines burn oil, which draws oil straight from an injector on the intake manifold into the burner. This adds to the pollution level in the exhaust. Pollution is not appreciated by nature.

#3. Rotor Sealing.

When the rotor’s temperature varies wildly, rotor sealing can be difficult in rotary engines, which further adds to the engine’s emissions.

The suction and burning happen at the same time but occur at separate locations in the engine housing: meaning the temperature at the top of the engine housing is lower than the temperature at the bottom.

#4. High Emission Rates.

Wankel rotary engines are not well-known because these engines have a high emission rate. Not achieving the fuel economy or emissions standards today is due to the sealing issues in rotary engines, inherent burning of oil, and less-than-efficient burning.

#5. Poor Fuel Economy.

Wankel engines consume more fuel per mile compared to reciprocating engines: Higher fuel usage results in higher gasoline costs.

Advantages of the Wankel Rotary Engine Over Reciprocating Engine

- Wankel rotary engine is more compact, lighter, and smaller than reciprocating engines.

- It is easier and cheaper, because of fewer working parts, for mass production. These examples are: connecting rods, crankshafts, valve mechanisms, and so on.

- Its balancing is easier; there are no reciprocating parts. Road tests have proven that is practically vibration-free.

- Wankel engine volumetric efficiency is usually higher than 100%.

- The power to weight ratio of the Wankel engine is considerably higher than any reciprocating engine.

- The Wankel engine requires a lower running cost than the reciprocating engine.

- The Wankel engine doesn’t have to use overdrive; the power generated is sufficiently high.

Disadvantages of Wankel Engine

- Fuel consumption is high for low speed and high oil consumption per B.H.P.

- Torque speeds are low.

- The braking effect of the engine is lessened.

- The speed in the transmission is decreased because of the high engine speed.

- If the ignition is fine, it is necessary to change the spark plugs every so often. This has been addressed with transistorized ignition.

- The major problem in developing the Wankel rotary engine was the sealing problem, which has been worked through for the most part.

- Cylinder distortion may happen due to the close distance of the inlet and exhaust ports.

- Extremely high exhaust gas temperatures of about 1600 degrees F present some problems with manifold and silencer design.

Uses of Wankel Rotary Engine

The Wankel rotary engine is used in the following ways:

- The first Wankel rotary engine was produced in the Mazda 12A.

- It is designed to generate a light, reliable engine that is relatively powerful in plane applications.

- Wankel engines are also popular among motorcycle manufacturers because of their small size and attractive power-to-weight ratio.

- With compact size and high power-to-weight ratios, Wankel engines may also be used in electric vehicles to provide supplemental power for range when electric battery levels are low.

- Increasingly smaller Wankel engines are observed in additional areas such as auxiliary power units for go-karts and personal watercraft.

- Because of their simplicity, the Wankel engine can readily be adapted into mini, micro, and micro-mini engine designs.

Difference Between Rotary Engine and Reciprocating Engine

| Rotary Engine | Reciprocating Engine |

|---|---|

| A rotary engine consists of four sections, each of which performs a specific function: intake, compression, combustion (or ignition), or exhaust. | A reciprocating engine is one of two types of combustion engines, which produces energy by combusting fuel. |

| A rotor rotary engine has three moving parts, which are, two rotors and an output shaft. | Simple reciprocating engines have at least 40 moving parts. |

| The rotor in a rotary engine rotates continuously in one direction. | The pistons in a reciprocating engine suddenly changes direction. |

| A rotary engine’s main moving parts move more slowly, thereby facilitating reliability. | A reciprocating engine’s main moving parts move at high speeds, thereby decreasing reliability. |

Closing It Up

We addressed many of the advantages of the Wankel engine, and many of the downsides.

These engines may have a place in the world, ultimately, due to the extra maintenance required to keep it running well and the cost of driving one.