As a homeowner, you will definitely have to use screws at some point – and likely many times. You may have already noticed there are a many different types of screws in the hardware at your home store.

While most screws seem to be the same, each screw was created for different purposes. What screw will you choose for your project? Here is a list of 26 different screw types to know as a hobbyist.

What is Screw?

A screw is a metal tip that has a sharp point and has helical threads wrapping the length of its shaft and has a slotted head that is twisted to join objects.

Screws are one variety of fastener that holds materials together with tools such as hammers or screwdrivers.

Screws are often made to be self threading, which means the thread cuts in the material as the screw is turned, and creates an internal thread that pulls the fastening material together and prevents it from coming apart.

These come in many shapes and sizes, and each one has different uses. Screws may commonly be round, flat, short, long, etc., but it will be hard to know the right or different types of screws for your project as there are many types.

To try to give you a more thorough understanding of the different types of screws, we bring to you 26 types of screws that you commonly used in the field or at home. So read on to know the different types of screws.

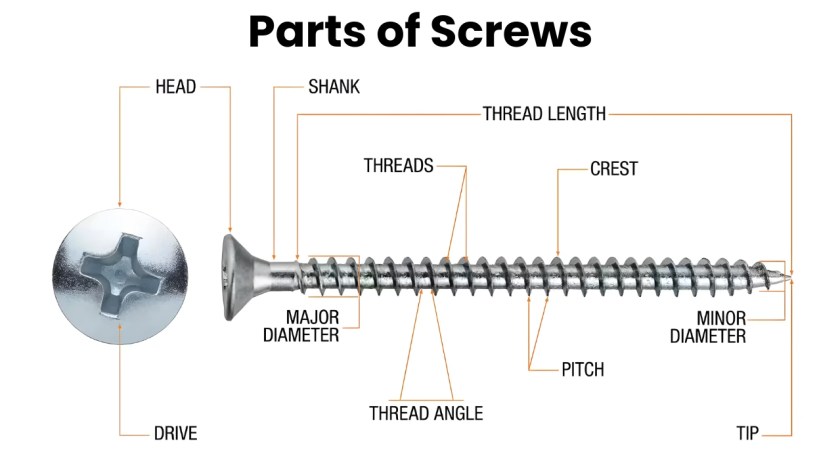

Parts of Screws

The main parts of the screw are:

- Drive

- Head

- Threaded shank

- Non-threaded shank

- Thread

- Thread length

- Tip

- Crest

- Screw thickness

#1. Drive.

Drive is another name used for screw heads. The drive is a slot that the screwdriver tip fits into, to turn the screw.

There are many different drive sizes and styles available, so it is a good idea to have different types of screwdriver tips in your toolbox.

#2. Head.

The head is the part of the screw that is at the top. All types of screws, either loosening or tightening can take either. The head is always larger than the shank and the thread. The head has surfaces which allow for a screwdriver or a wrench to be applied.

#3. Threaded Shank.

This is the tapered area of the screw where the threads and helical are located. This is where the screw makes its grip on the bodies being joined.

#4. Non-threaded Shank.

The non-threaded shank is the long part of the screw that does not have threads. The non-threaded does not need to be included in each type of screw.

It is customary located in the upper end of the screw, it gives room for the wood screw tip to pull the screw into the wood, similar to the wood screw.

#5. Thread.

A thread can be defined as a ridged or similar portion to a helix or conical spiral located on the inside surface of a screw or the outside surface.

The distance that separates each thread from each is referred to as the pitch; for instance, some screws have short threads that are close together and some other screws have larger threads that may be further apart.

#6. Thread Length.

Thread length is either total full or partial. There are full screw threads and partial screw threads.

#7. Tip.

The tip is the lowest part of the screw where the screw enters the object you are inserting the screw into. The tip usually helps to start the screw through the two bodies back together.

If it doesn’t have a tip then it is a bolt and requires a hole to be made already. There are, however, screws that are without a tip which has a thread.

#8. Crest.

The crest of the screw thread or insides and outsides is the most important part of interest and is where you have the thread valleys in the thread.

#9. Screw Thickness.

The thickness of the screw is measure at the two diameters that is major and minor at the part of the thread. The major is the diameter at the thickest part of the screw thread. The minor thickness is the diameter at the base of the screw.

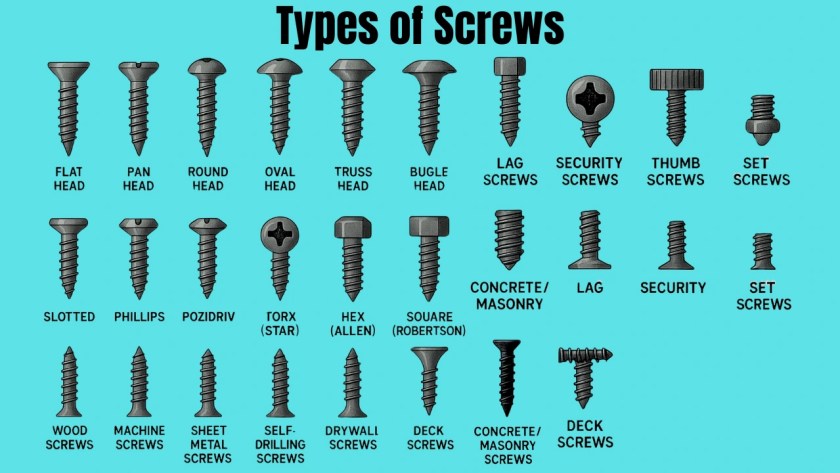

Types of Screws

Following are the types of Screws:

- Carriage bolts

- Decking screws

- Double ended screws

- Drywall screws

- Eye bolt screws

- Framing screws

- Fillister head screws

- Hex cap screws

- Hammer drive screws

- Lag screws

- Machine screws

- Masonry screws

- Oval head screws

- Pan-head screws

- Particle board screws

- Square head bolts

- Self-drilling screws

- Set screws

- Shoulder screws

- Sheet metal screws

- Socket-head screws

- Thread cutting screws

- Washer-faced screws

- Wood screws

- Weld screws

- Tamper-proof screw

#1. Carriage Bolts.

Carriage bolts are a type of screws that is used to join metal to metal, or wood to metal. The carriage bolt is unique from other bolts since the head is shallow, rounded, and mushroom-shaped along its shank.

Use of a domed head design for the carriage bolt can prevent it from unloosening from just one side.

The increase in size of the head can also help to prevent the screw from being pulled through a wooden structure. A domed head nut helps the carriage screw from unloosening from the side that is not covered.

#2. Decking Screws.

Deck screws are screws used to join decks (roofless flat structures) mainly used outdoors where the deck screws are made from stainless steel or carbon steel to join wood or composite boards together.

Deck screws are specially designed to resist coatings like rust and corrosion that expose it to damp environments. They typically have covering threads with sharp edges and narrow points.

#3. Double Ended Screws.

Double-ended screws are screws used for a joint under the object.

Double-ended screws are in general use to two pieces of wood or two parts that are able to move together.

They have two pointed ends that can be inserted into two surfaces to form a joint that is hidden.

Double-ended screws are headless screws with rotating threads at both ends which can be screws with machine screws on both ends or a combination of wood screws. Double-ended screws are very easily attached or potentially detached from the user. These types of screws are easy to use.

#4. Drywall Screws.

Drywall screws are commonly used to attach drywall panels to softwood or metal studs. These screws are a special type of self-tapping screw, specifically designed with a cylindrical shaft.

They have deeper threads than most screws with a heightened pitch and longer length that help to not loosen when embedded in the drywall.

They also feature a rough thread and a flat tip. The tip makes them easy to drill into drywall’s surface, but a power screwdriver is needed.

Drywall screws provide a tighter grip than deck screws but lack the same corrosion resistance. They do not require a pilot hole due to the drilling tip embedded in the screw.

#5. Eye Bolt Screws.

An eye bolt is a type of bolt that has a loop shape on one side and has threads on the other side of a shank like other bolts. It is a highly functional screw that simply attaches a secure eye to a structure system so it is easier to tie ropes or cables.

These are very easy to carry in metal and provide stability plus strength so that an object can be easily pulled out or lifted with the aid of rope. Eyebolt screws are typically used as a connection point for anchoring or pulling or pushing or hoisting applications.

#6. Framing Screws.

Framing screws are screws designed for some applications used with sheet metal, wood, composite decking, cement fiberboard, and other materials. They also work with brittle materials and different hardwood floors.

They have similar functions to circular saw blades in the sense they small amounts of “sawdust” from getting near the edge of the hole being made with the screw. Framing screws are often used for outdoor applications, like kitchen cabinets or when building a deck.

#7. Fillister Head Screws.

Fillister head screws are slotted head machine screws similar to machine screws. However, these pan heads have larger heads that can be useful for attaching metal or wood to metal. Cheese head screws is commonly referred to.

The heads of these screws are primarily selected for counterbore holes. These deep sizable heads make these screws good for reciprocating and swelling drives.

But more generally, cheese head screws are a good selection for general tool manufacturing and automotive applications.

#8. Hex Cap Screws.

Hex cap screws are hexagon shaped bolts (6 sided), with a punctured hex head and washer face on bearing surface.

Hex cap screws are for attaching wood or metal to wood. These screws have tight tolerances on body dimensions and include a chamfer.

Hex screws feature short steel threads, making them suitable for interior home improvement projects.

These screws also feature a flat washer under the screw head and provide exacting application. Hex caps are used in docks, bridges, road structures, and buildings.

#9. Hammer Drive Screws.

These screws are called self-tapping screws. They are usually made with rounded heads which have no slots. Hammer drive screws are used to attach nameplates or wall signs, as well as to seal drain holes.

They are highly effective for use in corrosion resistant tubular structures. The screws act like high-speed nails, as they are driven using a hammer or mallet through the holes for fast assembly purposes. However, prior to their installation it does require a small pre-drilled hole to fully install.

#10. Lag Screws.

Lag screws are used in heavy work and are often used in construction to connect pieces of wood or some other heavy materials. They are considered a rigid screw coming in hexagonal or square heads with thick threads to allow it to hold up to heavy workpieces.

The lag bolt makes a long-lasting connection just due to its length. This is why they use in some materials that may undergo heavy force or can hold heavy loads.

These screws are usually much heavier than traditional bearing wood screws. These screws are definitely different than standard wood screws or sheet metal type screws.

#11. Machine Screws.

A machine screw fastening parts has a socket in its head, so it can be turned using a screwdriver. Machine screws are fasteners that aid in holding parts of machines in applications, eg electronics, engineering, and manufacturing equipment.

Machine screws are fasteners which are specifically used to fasten a tapped hole to the surface with a nut. The screws are subject to stretching when tightened together, the tensile loading holds the parts together. Typically the pointed end to the screw is used to connect metal parts together.

Machine screws are now made from nearly any material including nylon, brass, stainless steel, and carbon steel.

#12. Masonry Screws.

Masonry screws are heavy-duty screws for fastening materials such as concrete, CMU, mortar joints, and brick. They can be made of stainless or carbon steel, with or without a rust coating.

To fit a masonry screw it requires a pre-drilled small hole using a carbide bit or hammer drill. Masonry screws are available in either flat head for countersinking, or hex washer head for resting beside the pre-drilled hole.

#13. Oval Head Screws.

These screws typically are in the shape of undercut or trim heads with shorter screw lengths giving a longer thread grip. In the case of oval-head screws, the screws are essentially close to countersunk with the screw head about half-way above the surface.

The oval countersunk screw heads have a rounded finish top and are generally used to cover switches.

They are also thought of as a good option to help make the finished product more appealing. There are typically two types of oval screws, rounded head screws and Phillips oval head screws – round head – Phillips oval head.

#14. Pan Head Screws.

Pan head screws are one type of non-countersunk screw head made from wood.

These are also self-tapping, self-drilling, and machine screws. Pan head screws have a wide head and a flat bearing surface, with a flat top and rounded sides that sits on the material it fastens to.

Because of the increased diameter and height of the head, the depth of the drive slot is deeper, which allows for the most torque with less chance of damaging the screw. Pan head screws with a single cut in the slotted heads are a pakhead screw that will work in any slot screw driver.

The main purpose of the screw is to secure metal components like machines and automotive engine parts.

#15. Particle Board Screws.

Particle board screws are fully threaded screws. These screws have the advantage of a longer thread, which gives them greater engagement and a greater pulling force.

These screws are designed for use in composite wood, like laminated particle board, or craft wood. Thus, cabinet makers utilize them in both domestic and commercial joinery.

Particle board screws are similar to drywall screws, but they are offered in shorter lengths than standard drywall screws. They are simply lightweight and easy to carry and manipulate. In terms of cabinetry, cabinets makers use them for either domestic or commercial cabinetry.

#16. Square Head Bolts.

Square head bolts are similar to hex cap screws except they have a square head with four edges instead of a hexagonal head with six edges.

They are often referred to as bolts, but are also referred to as screws because they work with a spanner. These screws are partially threaded along a shoulder under the head.

The application of the square head screw determines the size of the head of the bolt. Square head screws are used to tighten the nut as well as two parts together. The square head bolts and screws were the standard of the industry before the hex became important.

#17. Self-drilling Screw.

Self-drilling screws have a sharp pointed end that nearly resembles a drill bit and has cutting threads in order to be useful tap holes in installation.

Self-drilling screws have a tip like a drill and, therefore, do not need to pilot holes. Typically, these types of screws can be used for quickly drilling holes in metal and wood.

Self-drilling screws are typically denoted by their point and flute tip. They do the drilling and tapping of holes in harder materials for you, avoiding the usage of the tool. Because of the point at the end, which is curved like a twist drill, self-drilling screws are easily identified.

#18. Set Screws.

A set screw fastens an object within or against another object (e.g. a pulley or gear to a shaft) by applying pressure or friction.

Set screws are commonly used without a nut and are threaded for assembly into a threaded hole drilled in the two parts.

After the screw seats into the first object, the shank of the set screw is pressed against the second object and works to fasten the two objects together as a clamp does. These screws are often “headless”, and are fully threaded, meaning they fit entirely in to the hole.

#19. Shoulder Screws.

This screw fits into one part and gives a freely rotating pin joint connection in the other part. The screw consists of a large diameter shank just below the head and a smaller diameter threaded length.

With this design, a shoulder screw can be fittingly attached to one part without locking the other part, providing it with axial clearance. Shoulder screw designs permit rotational versatility since they act as a shaft for rotating parts like shoulder bearings.

#20. Sheet Metal Screws.

Sheet metal screws can attach or hold two sheets of metal to another type of metal, such as tubing, along with fastening two pieces of metal together. These screws come in flat, round, or hex screw heads.

The sheet metal screws come with pointed ends and with a fine thread on the shank. A sheet metal screw works by drilling into the sheet metal and has a fully threaded shank.

The benefits of using these screws are excellent penetration, superior holding, and corrosion-resistant.

#21. Socket Head Screws.

A socket cap screw is a machine screw with a cylindrical barrel-shaped head that has a hexagon shaped receptacle. Because of their cylindrical head and internal wrenching features, they can be used in applications where externally dampening fasteners will not be preferable.

These screws are excellent when you need a fastener that sits under the surface of the material. Wherever a joint is required, they can provide very strong and reliable, as well as being resistant to corrosion. Additionally, they provide an attractive and quality finish.

#22. Thread Cutting Screws.

These screws have sharp edges because the depth of the hole is just slightly longer than the screw depth, which will prevent the metals from locking in the device. Thread cutting screws are commonly used with wood and metal.

The intention is to reduce the build-up of internal tool stresses, making these ideal for extremely hard materials. It does not have a cutting edge like a thread-forming screw, which becomes a challenge with low compressive materials.

#23. Washer Faced Screws.

Screws like these serve as springs to reduce the distance between the nut and the screw head and are available in several types and sizes.

There are historically some types that have teeth to penetrate the material surface and lock the screw head into the workpiece. In this type, the washer face is located just beneath the screw head to provide a smooth bearing surface for easy tightening.

#24. Wood Screws.

Wood screws, as the name implies, are used for fastening wood. They are generally made of, brass, steel and bronze materials. Screws for wood can have a few types of threads and heads.

The screw tapers off as it locks towards the head, with a wider diameter than the tip of the screw.

The screw can also have a full or partial thread at the shank depending on the application. The size of the head of the screw depends on its application.

#25. Weld Screws.

These need to be welded to a metal surface, with a shaft, to hold the item in place with a nut and washer. The screw is first welded to the plate by melting a specially created tip on the screw, and then on the plate by means of a high powered electrical pulse.

The welded screw protrudes from the head to allow welding without any holes. The stud is then welded to the piece of metal resting on the weld plate. They are used in automotive, industrial, marine, construction and aerospace work.

#26. Tamper-proof Screws.

Tamper-proof screws resist removal after being installed. They can be used in buildings or areas that the public has access to in an effort to control or prevent vandalism.

These types of safety screws can be tested by their unique drive which results in great difficulty tampering or disassembling. They are typically used in prisons, which permits materials such as car license plates, gutters, and grill bars to be secured.

Wrapping It Up

You can select from among wood screws, deck screws, and other specialty screws designed specifically for machining, woodwork, or metalwork. Proper screw selection will make your project easier to complete!

Now that you know that there are many different types of screws, selecting the proper screws for your material will help you have the best experience with your project!