Nails vary in sizes, materials, and shaft designs to deliver maximum holding power in wood. This guide will help to ensure you select the correct size and type of nails for your application.

What Is A Nails?

A nail is a small metal piece that acts as a fastener, a peg to hang something, or sometimes a decorative piece. It is well-known that nails are common in woodwork and building.

Nails have one pointed end and one flat head or are made without a head altogether. Nails are generally driven with a hammer or a pneumatic nail gun.

The main function of a nail is to hold the material together in the axial direction by friction as well as a shearing force. Sometimes the tip of the nail is bent or clamped after it is driven in to help prevent it from coming out.

Nails are made in a wide variety of shapes for specific uses, with a different shape and design for each use. This guide provides the different types of nails so can you come up with the best nails for your project.

Parts of a Nails

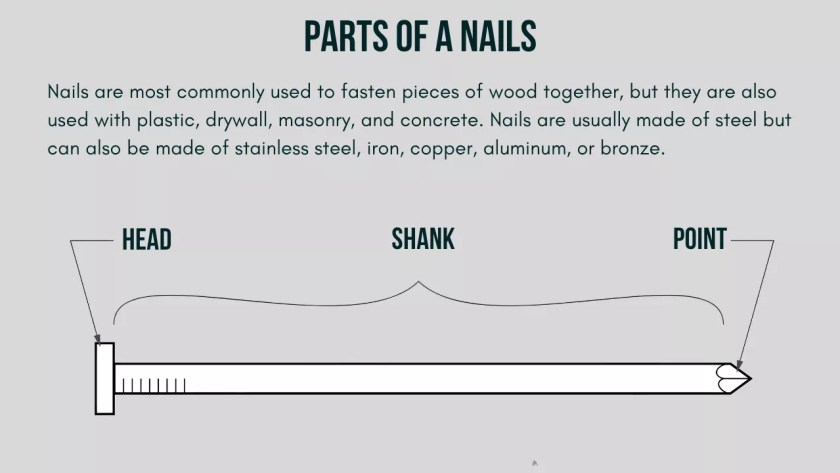

Nails have four common parts:

- Nail point

- Head

- Shank

- Nail coating

#1. Nail Point.

The points of nails are diamond-shaped, which is the most common cut for general use. Having a diamond-shaped point cuts your driving effort down to a minimum. Some nails are made with blunt points, which can be harder to drive but may help to prevent wood splitting, but they require more driving effort.

#2. Head.

The top of a nail is the head. The heads of nails are designed to accept the pointed end of the nails, and its shape often prevents the nail from slipping or digging into the wood when used to counter a nail.

Nails come with many different type heads that each have their own characteristics. Some type heads are round heads, counter sunk heads, flat heads, checkered heads, clipped heads, etc.

#3. Shank.

The nail shank is the part that does most of the holding. Shanks hold the nail in place, even under the most extreme pressure. The nail shank is held in a position between the fibers of the wood, which press against the shank.

It is because of this pressure, that is requires significant effort to pull a nail from the wood. Nails are typically made with a couple different type shanks, that are smooth-shank, spiral-shank, ring-shank nails, or annular nails.

#4. Nail Coating.

Coat nails are not coated, but some nails may be treated with the material to lubricate the shank of nails to make them easy to drive into wood, or to help them hold after driving.

A process call galvanization takes place during the making of nails, which a zinc coating is applied to nails to provide some protection against corrosion.

Types of Nails

Here are the main types of nails:

#1. Common Nails.

Common nails are for construction, structural, or framing duties. Common nails usually are wider headed nails with a diamond shape point and thick nail leg. These types of nails are the best for fastening jobs that required strength over appearance.

In many construction scenarios using “common nails” for their distinction and not points may be better suited for situations where appearance is less of a detail but functionality is the most concern.

Common nails are heavy duty and design for heavy or more strength sone work.

#2. Framing Nails.

Framing nails are typically used in heavy construction and often gun fired when it comes to attaching to wood. Open frame nails are used to affix, or used for crafting your projects.

Framing nails can be heavy duty and durable with competitive pointed end that can drive forces through the material without splitting.

The framing nails showed with stick and geared fring for both building and other wood work or other projects to make adequately solid framing.

Framing nails can also may be thinner act different diameter points that can be longer being versus a framing nail. One way its framed would be from looks of the finish and flush plans and for slimmer work, in to uses of framing or other woodwork as for different design projects to build framing.

#3. Box Nails.

Box nails are essentially more similar to a regular nail but it was thinner shanks to fit on lighter pieces of wood and to make boxes. The thinner shank usually means smaller diameter, which means there will be less likelihood of splitting the wood components when you drive the nails.

While thinner box nails are often galvanized also as to corrode or problem over-every other pulled metal and is lighter. Most of time box nails using lightweight has ultimately and reasons of its because of less resistant or with other nails less, or may are nailing it lightly held, unusually.

Box nails will often not be used and are less structural in applications, because of low strength or them then holding, as the case of the woods stability and shape are prevented for.

#4. Deck Nails.

Stainless steel deck nails are preferred for decking, as they are more resistant to corrosion with less discoloration for woods like cedar. These nails often have a checkered head to have a better contact with the hammer.

Deck nails typically have smaller diameter shafts to help prevent splitting and the shank may have rings or a spiral flute that help ensure they remain secure with exposure to drying and weathering on the deck. Deck nails are intended for outdoor use and can be used with treated lumber.

#5. Sinker Nails.

Sinker nails have thinner shanks than common nails, flat heads, and are often coated, thus making it easy to quickly drive them flush or counter-sunk. It may also be easier to drive them flush because they have a checkered head that helps prevent the hammer from slipping off of the nail head when driving.

Usually the nails are coated with either cement or vinyl, providing lubrication when driving as well as increasing holding power when cured.

After the nail is set, the rings on the head will help hold the nail while the vinyl cools and solidifies to form an adhesive bond. These nails are used on framing and general construction projects.

#6. Masonry Nails.

Masonry nails are strong nails for fastening into walls, ceilings, and anything else. They’re made from solid, high-strength materials, such as steel, so they can be driven into various masonry surfaces, such as brick and concrete.

The grooved shaft keeps the masonry nail attached to the mounting surface, preventing it from moving when installed. Extruded masonry nails are typically shorter, thick, with rounded curved or oval shanks.

Medium-duty applications will be appropriate if you do not want to use an anchor system.

#7. Roofing Nails.

A roofing nail is a small nail with a large head and a barbed shank used to fasten roofing paper or asphalt shingles to a roofing board. They are technically the best nails nailed for asphalt shingles, roof felt, or roof decking (or sheathing).

They are typically made of aluminum, or have a finish to protect from corrosion. Some types will have a gasket underneath the head to create a weather resistant seal. Other types may be slightly bent to increase holding power.

#8. Spiral Shank Nails.

Spiral shank nails have shanks that typically resemble screws. The spiral thread of the shank rotates the nail during driving, creating an interlock of thread-like fasteners, which creates clearance.

These will twist and form their threads across the wood being nailed into during driving. They are designed to drive smoothly through hardwoods and dense material while resisting getting pulled out. Spiral shank nails are used for a variety of applications including flooring, siding, decking, pallets, and truss rafters.

#9. Joist Hanger Nails.

To attach the hangers to the joists, the user just needs to use the galvanized joist hanger nails that are 1-1/2 inches long. Joist hanger nails are generally shorter and heavier gauge nails that provide higher holding power without going completely through the wood.

These nails have a strong shank to provide strength, and they are usually hot-dipped galvanized, so they can be used outdoors and with treated wood.

#10. Duplex Nails.

Prior to the introduction of duplex nails, regular nails were extensively employed as formwork. Duplex nail or double-headed fasteners are commonly used for building temporary structures including bracing, scaffolding and concrete formwork.

These are to be used temporarily; they are intended to provide easy removal so they do not go fully into the material when secured. Each has two heads securing the nail against the work. The second head for easy removal.

#11. Pole Barn Nails.

Pole barn nails are intended for use in load-bearing wooden structures where extra holding capability is desired. These type of nails are commonly selected for construction projects that consist of wooden poles, which are going to be set in the ground to provide a foundation for construction of the building.

Pole barn nails are typically manufactured from a type of high carbon steel that provides an increased hardness. These nails are ring shanked for holding power and have a rust resistant finish that is compatible with pressure-treated lumber.

#12. Connector Nails.

Connector nails connect structural hardware (ex: framing angles, raft ties, etc.).

With a conical shape on the bottom of the head, connector nails are highly recommended for structural assemblages and wood instantiation applications to realize a published load-carrying capacity.

#13. Cap Nails.

Cap nails attach roofing felt, house wrap, tar paper, and insulating foam board. They are different than common nails because they use a steel shank and a polyethylene cap to avoid leaks.

These types have a spiral shank that holds fastener in position. These nails also have a plastic cap just below the nails head to hold wrap, felt, or insulation in place without tearing.

#14. Trim Nails.

Trim nails are used for exterior purposes of homes. Trim nails are used for the gutters, fascia, and soffit boards and also used in installer trim and exterior trim.

#15. Finishing Nails.

Finishing nails are steel, slightly larger than brad nails and are used for finishing; its small cylindrical head was easy to remove and there will be a filler that covers the hole caused by the nail.

Also used in carpentry and cabinetry, and are acceptable for molding, the smaller diameter shank greatly reduces the chances of splitting the workpiece.

They are lighter than common nails and have a small head. It is usually a range of 16-gauge to 10-gauge and is very strong.

#16. Brad Nails.

Brad nails are steel wire, usually 18-gauge, and thick in size. Braid nails are more subtle than common nails and are great for projects that demand a neat look.

They are smaller in size and have less holding power and therefore we do not recommend using them for all structural, joinery or framing. But are suitable for woodworking, cabinet and craft work.

Like the finish nail, brad nails have their heads only slightly larger than the diameter of the shaft to allow for counter sinking along with their smaller heads.

#17. Pin Nails.

Pin nails can also be referred to as thin nails, as their lasting holding power is very minimal. The pin nails use to hold something in position temporarily. These are small in diameter (23 gauge) and typically available without a head.

Despite the minimal holding power, because pin nails are invisible, they can be fastened with thin veneer and glue to merely secure small pieces of moldings and trim. Pin nails are interchangeable between nail guns and are very commonly found.

#18. Drywall Nails.

The drywall nails have additional holding power with their ring or barbed shank. The ring or barbed shank allows nails to be placed further beneath the surface of the wallboard to conceal them and limit tearing of drywall paper.

The drywall nails are also equipped with long diamond-shaped points that are designed to limit splitting of wall studs. The nails will primarily be used for the attachment of gypsum board and drywall. Many times people will choose to use drywall screws, which are similar to drywall nails.

#19. Panel Board Nails.

Panel board nails are produced with a small head and used to attach wall panels to wood furring and studs. Some are manufactured with ring shanks to provide additional holding power and are occasionally colored to coordinate with the installed panel.

#20. Flooring Nails.

Flooring nails are available in several variations depending on the flooring material they will be attached. Common types have rings like screws for attaching plywood or other subfloor materials.

The rings help lessen slippage and ensure anything is secured safely. They are manufactured for use with pneumatic Nailers to secure certain types of hardwood floors.

They can be found in shorter styles like spiral nails which are used to secure floor trims and longer ones for securing subflooring.

#21. Furniture Nails.

Also referred to as upholstery nails, they secure upholstery material to furniture or leather sofas, for trim. Furniture nails are manufactured to be hammered 2.5 cm into the front or back of the seat in the chair.

The main purpose of the furniture nails is to hold the upholstery fabric to the wooden chair frame. Furniture nails are typically short with a relatively large decorative head.

#22. Annular Ring Nails.

Annular ring nails have rings on the shank that provide grip and additional resistance in wood. These nails are made of carbon steel and do not have a rust-resistant coating so will rust in moist conditions.

They are used to install subflooring to keep the floor from creaking due to their additional holding power.

The threads on the nail have excellent holding power in concrete block and masonry applications. Additionally, they are sometimes used in plywood, underlayment, deck materials, siding and roofing.

#23. Miscellaneous Nails.

Miscellaneous nails are less common nails used by both laypeople and even professional construction workers.

These nails are coated with cement and resin for holding power and a drywall nail is used for the created screws used for hanging wallboards. In fact, any type of nail that does not fit the regular category or is used unusually can fit into this category of nail.

#24. Tacks.

Tacks are a small style of nail that have a broad and flat head, used to fix carpets to the floor and to pull clothes on wood. In fact, tacks are used to repair floorboards, fix rugs, and pull fabric on a piece of wood.

#25. Hardboard Nails.

Hardboard nails have a diamond-shaped head for that is barely seen when hammered fully into the hardboard. Hardboard nails are made with lengths that range from three-eighths to one and a half inches.

Sizes of Nails

Nail lengths of most types can be indicated by the inch or penny system, abbreviated with a D (16D nails). The penny system is originally supposed to indicate the length of a nail. The higher number is the longer length; here are some nail sizes:

| Penny Type | Length (inch) |

|---|---|

| 2D | 1 in |

| 3D | 1 – 1/4 in |

| 4D | 1 – 1/2 in |

| 5D | 1 – 3/4 in |

| 6D | 2 in |

| 8D | 2 – 1/2 in |

| 10D | 3 in |

| 12D | 3 – 1/4 in |

| 16D | 3 – 1/2 in |

| 20D | 4 in |

| 30D | 4 – 1/2 in |

| 40D | 5 in |

| 60D | 6 in |

Tips for Using Nails

Here are some tips to keep in mind when using nails:

- Drilling a pilot hole will help a nail penetrate harder wood or the end of wood more easily.

- To dull the tip, turn the nail upside down and strike it on the tip several times. Dulling a nail will require more force to drive it in, however, it will lessen the chance of the wood splitting.

- Nails driven through or at angles to the grain of the wood help keep the nail in place. Nails driven with the grain of the wood will come out easier.

- For working with wood and being worried about rust damaging nails, use aluminum nails; aluminum is more rust resistant than coatings advertised as rust resistant and aluminum is usually found on screens or metal siding.

- When hammering into cedar or redwood, stainless steel nails contain no corrosive or degradable products because they are made of stainless steel and they will not stain or streak the wood.

- Driving multiple nails in the same grain line when nailing increases the likelihood of the wood splitting.

- When hammering nails into masonry, wear safety goggles.

Conclusion

As I already mentioned, a nail is a type of fastener specifically designed to fasten one or more objects to each other. Nails are made for building possible large and permanent structures. I hope you grasped that there are many types of nails and each nail has a certain use.