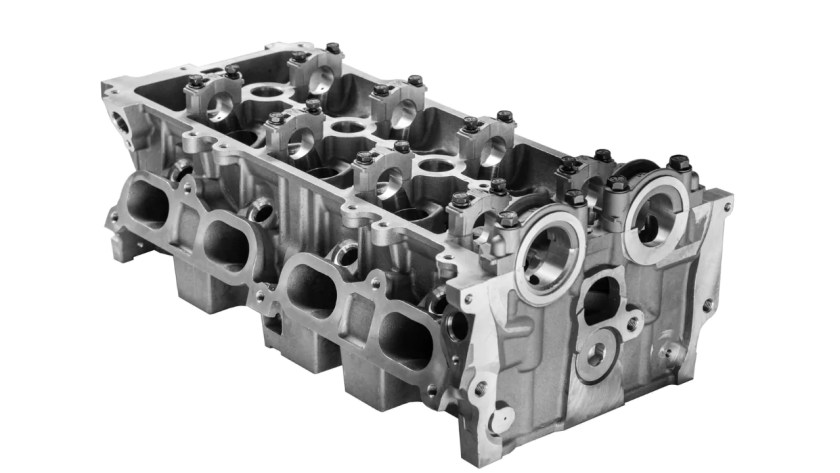

In an engine, the top of the cylinder is closed with a separate cast piece called the cylinder head. The cylinder head is bolted to the upper part of the cylinder block.

This joint is covered by a head gasket. It consists of a combustion chamber, spark plugs, and sometimes valves (in the I and F-heads).

In most engines, the cylinder head includes passages that deliver air and fuel to the cylinders, and which allow exhaust gas to exit.

The cylinder head is usually made of gray iron or aluminum alloy. Aluminum has the advantages of being lightweight and having high thermal conductivity.

Now, we will discuss the construction of the cylinder head.

What is a Cylinder Head?

A vehicle’s cylinder head is attached to the engine block, with the head gasket sealing the two components together.

The cylinder head has openings for spark plugs and valves. In an overhead cam engine, the cylinder would also have an opening for the camshaft.

There are several passageways or tracts of different sizes throughout the cylinder head. Some of the tracts provide airflow to the valve. Other tracts provide an opening for the exhaust gasses to leave the motor.

When the cylinder head is bolted into place, the tops of the cylinders are sealed, forming the combustion chambers. The spark plugs point towards the combustion chamber to assist with combustion.

Located on top of each cylinder are valves that are opened and closed by the camshaft. An intake valve opens to allow the air-fuel mixture to enter the cylinder, and then later closes. While the piston moves up the cylinder, the air-fuel mixture is compressed until the spark plugs ignite the compressed fuel.

The expansion of the combustion gasses creates movement of the piston against the cylinder head. Once the combustion stroke is finished, the piston moves down towards the cylinder head allowing the exhaust valve to open, letting the gasses escape the cylinder. The timing belt or chain keeps the order of operations in check.

The cylinder head performs the following tasks:

- Seals the combustion chamber and cylinder block

- Houses the intake and exhaust valves

- Creates the shape of the combustion chamber

- Dissipates heat generated during combustion.

Construction of Cylinder Head

A cast head is detachable from the cylinder block so that debris causing carbon and valve grind problems can be cleaned. A flat piece of gasket material seals the cylinder head and cylinder block to maintain compression within the cylinder.

In some applications like racing car engines, a separate head is not installed. But a single piece cylinder block and head is more complex to make, is more expensive, and make internal engine parts less accessible.

Depending on the layout of the valves, the cylinder head may have camshafts, rockers and valves. Waterways are provided for valve and plug seating.

From the mechanical point of view, the design details of a detachable cylinder head are perhaps the most difficult.

The following should be considered when making detachable heads:

- The bore of the cylinder or liner should not be distorted by the pull of the holding down studs.

- The circulation of coolant in the cylinder head should be taken as far as possible to the top end.

- The holding studs must be distributed as uniformly as possible around the circumference of each cylinder, in order to obtain a sound gas-tight joint.

Now we proceed to define each of the components in the cylinder head.

Parts of Cylinder Head

The cylinder head features various holes connecting the cylinder block to the head, with ones for water jackets for circulation, cooling, and lubrication.

The cylinder head also houses key engine components like the inlet valve, exhaust valves, valve guides, injectors, and spark plugs.

The SI engine contains a combustion chamber as part of the cylinder head and there is an assembly for a heater plug and cylinder head injection. Also, there is a thermostat valve at the elbow of the radiator’s outlet for circulation. A combustion chamber is part of the cylinder head itself.

In this combustion chamber, petrol or diesel is burned through different intake and outlet manifold valves, including holes for providing oil to the cylinder at different moments.

The components of the cylinder head are as follows:

- Head gasket

- Intake and exhaust ports

- Head valves

- Head combustion chamber

- Spark plugs

- Fuel injectors

- Head camshaft

- Additional cylinder head parts

#1. Head Gasket.

The head gaskets are found between the cylinder head and the engine block. A head gasket is bolted on top of the engine housing. The gaskets serve as a seal between the cylinder head and the engine block. The gaskets stop the oil and engine coolant from leaking or mixing.

#2. Intake and Exhaust Ports.

The intake and exhaust ports are also part of the cylinder head. The intake port is meant to circulate the air through a channel into the cylinder head/combustion chamber.

Once the combustion process is completed or finished, the gases are taken out of the combustion chamber through the exhaust port. Otherwise, the gases will increase internal pressure which could cause the engine to explode.

#3. Head Valves.

The engine has valves that will close and open for the purpose not to let air or fuel enter the combustion chamber. In a internal combustion engine, each cylinder will have two valves. The intake valve is larger while the exhaust valve is smaller.

#4. Head Combustion Chamber.

The head combustion chamber is called the core of the engine. The air-fuel mixture burns here to generate the power to move the vehicle.

There are combustion chamber shapes and sizes available. Well, it really depends on the engine that you have and what the application of the vehicle is.

#5. Spark Plugs.

Spark plugs ignite the air/fuel mixture in the combustion chamber. Plugs are mounted on the cylinder heads, and their tips lead to the combustion chamber. The plugs are usually threaded to have a sealed airtight connection.

#6. Fuel Injectors.

You will also find fuel injectors on the cylinder head cover. In a diesel engine, injectors spray the fuel into the combustion chamber by means of an injection pump.

#7. Head Camshaft.

And the cylinder head also contains the camshaft. In this case, the camshaft opens and closes the valves. The crankshaft is a component of the engine block and uses a belt to drive the head camshaft.

#8. Other Cylinder Head Parts.

The cylinder head also has ports for the purpose of lubricating to cool the engine. Cylinder head port designs vary, just like all head designs. Basically, each type of construction aims to make each part efficient.

Function of Cylinder Head

The cylinder head is important to a motor vehicle and is a complex structure with many ports. One port is for operating, and the various ports are related and help define the value of the engine component.

It provides the mounting for components such as inlet and outlet exhaust valves and ducts, spark plugs, fuel injectors, and camshafts, plus provides paths for coolant, oil, and combustion gases.

The cylinder block absorbs the heat generated in the engine, and therefore provides the necessary cooling to avoid engine failure.

The cylinder head also seals the combustion chamber and acts as a powerful mechanical control over the engine. The cylinder head absorbs and retains the action taken on the combustion pressure of the burning gas.

Types of Cylinder Head

The cylinder head has been divided into several categories. It also depends on how the ports and valves are configured.

- Loop flow cylinder head

- Offset cross flow cylinder head

- In-line cross flow cylinder head

- Flat head cylinder head

- Overhead valve cylinder head

- Overhead camshaft cylinder head

- Water cooled engine

- Air cooled engine

Now let’s look at each type of cylinder head individually.

#1. Loop Flow Cylinder Head.

The inlet and outlet ports of a loop flow cylinder head are located on the same side of the engine. The cylinder head introduces gasses and then the exhaust gasses change direction as they exit.

In a loop flow engine, the starting inlet charge and exhaust gas escaping the engine swirl in the same direction, which preheats the inlet air.

However, when the inlet and outlet ports are aligned, there is not as much distance from one side of the head, which results in a smaller port area than you would have with a cross flow head.

#2. Offset Closet Flow Cylinder Head.

The term crossflow is defined when the intake and exhaust ports are located on opposite sides of the cylinder head. In crossflow cylinder head designs, gases are introduced to flow across the head. The crossflow type cylinder head referred here is designed diametrically opposite of the loop flow type, which has the intake and exhaust ports located on the same side.

Crossflow cylinder heads can also be operated by overhead camshafts, or by a valve train, which contains the camshafts in the cylinder block, and actuates the valves by pushrods and rockers.

Crossflow type cylinder heads have a performance advantage and are more efficient than loop flow type cylinder heads.

#3. In-line Cross Flow Cylinder Head.

The offset cross-flow type cylinder head shares some of the characteristics of the inline cross-flow type cylinder head. The contrast in their design is that the valves in an inline cylinder head are situated transversely and inclined.

Similar to the offset cylinder head, the inlet and exhaust ports, in an inline cross-flow type cylinder heads, are located opposite one another and on opposite sides of the cylinder head.

This is a design that is obviously superior to traditional designs concerning performance and is even better concerning efficiency. However, this option would be impractical because of the manufacturing cost.

The cylinder heads come in two varieties, depending on the amount of cooling needed:

#1. Water-Cooled Engine.

The head of the water cooling engine utilizes a number of water jackets to circulate the water. The water cooled engine system is both pressurized and sealed, which allows for that higher boiling point of water be achieved (well above 110 °C).

This means that the water can be used for a longer duration because it evaporates more slowly. The hot parts of the engine, such as the cylinder head and cylinder block, discharge their heat with the help of circulating water.

The water then flows through the radiator where a cooling fan draws air across the radiator to maintain cooler water. A liquid- or water-cooled engine is defined as any type of engine that employs liquid to cool the internal combustion (IC) engine.

Most modern motorcycles, automobiles, and other types of vehicles have liquid- or water-cooled motors.

#2. Air-Cooled Engine.

Air-cooled engines, which are very lightweight made of aluminum alloy, have fins for cooling. Air circulates over the hot engine parts to cool them down, which keeps the engine temperature in the operating range.

Most heat is lost through the exhaust system, while some heat is lost through the metal fins of the air-cooled engine. Some fins extend outward from the engine to transfer heat away from the engine into the air.

A fan forced cool air over the fins. An air-cooled engine dissipated the heat created in the atmosphere directly. Water or liquid-cooled engines used a closed-circuit system of circulating coolant.

The cylinder head is classified into three types based on how it performs:

#1. Flathead Cylinder Head.

These types of cylinder heads are a single piece of cast iron metal. Beyond its simplistic design, the flathead engine cylinder head type had disadvantages.

The valves are located on the sides of the engine block. This causes intake gases to be drawn through a 90° angle which created inefficient combustion and low compression. With the disadvantages of its design, the flathead cylinder is no longer considered common.

They are easy to manufacture and cost low, the head allows the coolant to flow properly. Because the flathead cylinder head is lightweight it allows for a compact engine. Common small engines used with flathead style cylinder heads can be found in lawnmowers, small tractors, and agricultural vehicles.

#2. Overhead Valve Cylinder Head (OHV).

Overhead-valve (OHV) cylinder heads are complex and also called I-type cylinder heads. It encompasses the valve train components, spark plugs, and the pathways for intake and exhaust gases.

Engines with overhead valves typically perform better because of the locations of the valves and the intake pathways. In this scenario, the flow of intake gases is smooth and fast due to more optimized pathways.

The benefit of installing this type of head is that the exhaust ports are also typically more efficient and it typically does not get hot compared to the flathead type. It also positions the camshaft more closely to the crankshaft.

#3. Overhead Camshaft Cylinder Head (OHC).

Cylinder heads allow for the inclusion of valve train parts, spark plugs and intake and exhaust ports; the head contains the camshaft.

In this case, the camshafts are located in the head of the cylinder. It can be either in the middle, in the middle of a row of valves, or at the top of the valve.

An OHC cylinder head is single or dual. In a single OHC cylinder head, the intake and exhaust valves use a single camshaft.

In the case of a dual OHC cylinder head, there are two camshafts – one camshaft for the intake valves and the other for the exhaust valves.

Cylinder heads are classified below, based upon how the ports and valves are located.

Automobile engines are classified into four basic categories based upon how the inlet valve and exhaust valve are arranged. These arrangements are designated the “L”, “I”, “F” and “T” heads.

Using the word “LIFT” will help you remember the four-valve arrangement and make this subject simple for you to learn.

#1. F-Head Engine.

The F-head engine is created by combining elements of the I-head and L-head engine. The exhaust valve in this type of engine is located in the cylinder block, whilst the inlet valve is typically located in the head. Both valves are operated using one camshaft.

#2. I-Head Engine.

In the I-head design, both the inlet and exhaust valves are housed in a single cylinder head. They are all operated by a single valve. Engines of this type are generally found in automobiles.

#3. L-Head Engine.

In both types of these engines, the inlet and exhaust valves are located side by side with one another, and are operated by a single camshaft. The combustion chamber and cylinder form an inverted L.

#4. T-Head Engine.

In the T-head engine, both the inlet valve and the exhaust valve are located on either side of the cylinder, which requires two camshafts to operate. One camshaft operates only the inlet valve, and the other operates only the exhaust valve.

Advantages of Cylinder and Head

The benefits of the aluminum alloy cylinder and head are as follows:

- It conducts heat but is about three times lighter than cast iron.

- It is lighter.

- It allows for an increased compression ratio with no detonation due to the heat conductivity.

- It cools better than cast iron while the engine runs.

- It allows for more power with lower fuel consumption because of the increased compression ratio and better cooling effect.

- It warms up faster and requires a smaller radiator.

Disadvantages

The following are drawbacks of the aluminum alloy cylinder and head:

- The engine costs more due to the quickly aluminum alloy.

- It is liable to be distorted out of shape by hold down studs because it has a low modulus of elasticity.

- Due to high thermal expansion, there must be more clearance between the piston and cylinder bore.

- Higher possibility of corrosion by cooling water.

- Sometimes, it is necessary to use cast iron valve seatings and spark plug inserts.

- The head may stick to the cylinder blocks due to inter-metallic corrosion between steel studs and aluminum alloys.

Applications of Cylinder Head

Here are the different applications of cylinder head:

- Cylinder head can be made integral with the cylinder block, and it is sometimes done on racing cars as it achieves a gas-tight joint.

- A detachable head type has the advantage over an integral type.

- Although, in some heavy duty engines requiring higher cooling rates, like on racing cars, they tend to use copper alloys.

Conclusion

As you can see now, it is a detachable metal that is fitted over the top of the cylinder block. It mainly serves its purpose is to close the combustion chamber of the engine from above. So I hope I have covered everything about the cylinder head parts, and how they work!